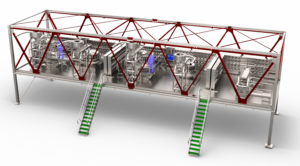

Enhancing its range of end-of-line solutions, ETPACK introduces its ETC20R Robotic Wrap-Around Case Packer. This combined solution, which incorporates the functions of carton volume forming, product loading, and sealing, is characterized by its compact footprint and ergonomics to adapt to various layout configurations.

Intermittent operation and high precision

Its intermittent operation with 2 to 6 axis robotic feeds ensures great versatility, precision in product handling, and proper arrangement in the cases. Format changes are quick, repeatable, and meticulous.

Multiproduct and cardboard architectures

This case packer is suitable for applications involving micro-fluted or corrugated cardboard cases, starting from a flat cut, including trays, cases, pouches, cans, clusters, boxes... with speeds of up to 20 cases/min. It is equipped with standard or application-specific grippers, capable of positioning products in various configurations (flat, on edge, upright, or staggered).

It is also predisposed for a wide variety of cardboard architectures (open cases, trays, sidewalk cases with adjoining and non-adjoining flaps, complete cases with front flap, displays with or without tops, and ready-to-sell), for packaging that closely fits your products.

Efficiency and cost optimization

It comes standard with an axis controller, servomotors, and a latest-generation hot-melt glue generator, offering high precision in glue application to optimize glue consumption. Several options can be integrated, such as automated changes, a vision camera system to inspect product quality, or a cardboard conformity check.

With the ETC20R robotic case packerETPACK offers an efficient solution to meet the productivity and flexibility demands of modern packaging lines.