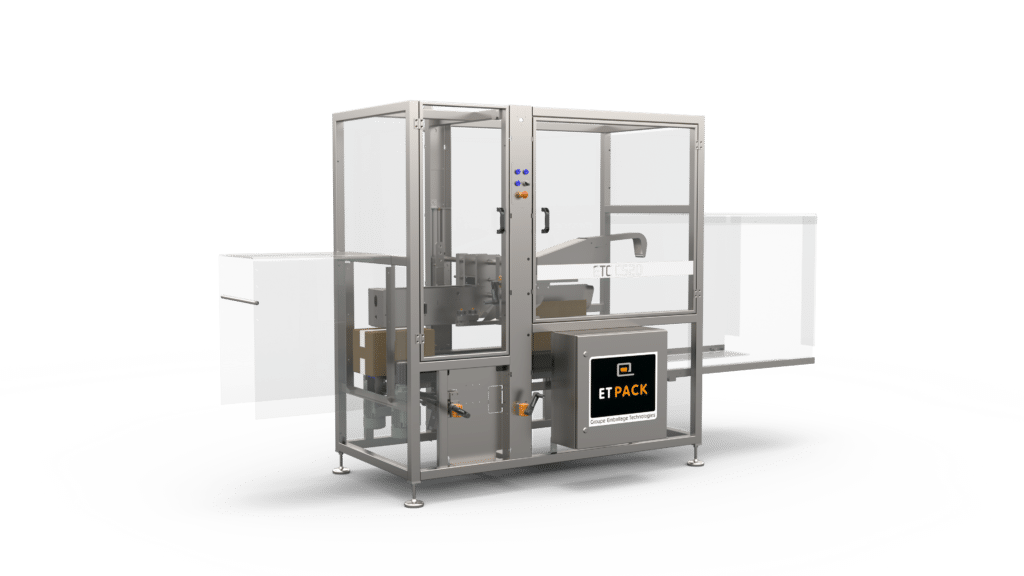

ETC CS20

GENERAL DESCRIPTION

- The box is picked up between the two side belts and conveyed through the machine.

- The belts have a special profile that keeps the body under control during transit

- The front flap will first be pre-folded by a small flap folding mechanism before being closed. As soon as the rear of the body is detected by a photocell, the rear flap will be closed.

- The flap folders will fold the large flaps during transport.he box is then sealed at the top with adhesive tape, and the closed box is removed from the machine.

- Lateral belt adjustments and height adjustments can be made using cranks. The adjustments of the two flap folders can be easily changed using a single handle, with the settings clearly visible on measurement scales.

- Options: Warning signal for detection of exhausted or broken ribbon; detection of free discharge by photocell; infeed guides equipped with separation module and stop; check for correct flap closure

TECHNICAL DATA

- Checking the adhesive

- Flow control: when the checkout causes an incident, the machine stops

- Minimum distance between tills: 350 mm

- Machine dimensions: 2660 x 975 x 1800 mm

- Pneumatic supply: 6 bar

- Standard mini/maxi formats :

- Length: 200 - 650 mm

- Width: 120 - 510 mm

- Height: 120 - 600 mm

UP TO 30 TILLS/MIN

COMPACT MACHINE & ERGONOMICS

Additional information

In the same range

Related products

-

FTE

- End of line, Palletising

- Discover

Description to come

Machine speed Final packaging Your product -

ETC20 loading

- Tray packing, End of line, Cashing, Wrap around

- Output up to 20 cases/min

- Hot-melt gluing of Wrap-Around cartons

- Discontinuous operation

- Discover

Machine speed Final packaging Your product -

ETC B33 Tray Packer

- Tray packer, End of line, Formatting cases

- Tray former

- Output up to 33 trays/min

- Discover

Machine speed Final packaging Your product