Robotic solutions

Industrial robotics: discover our solutions

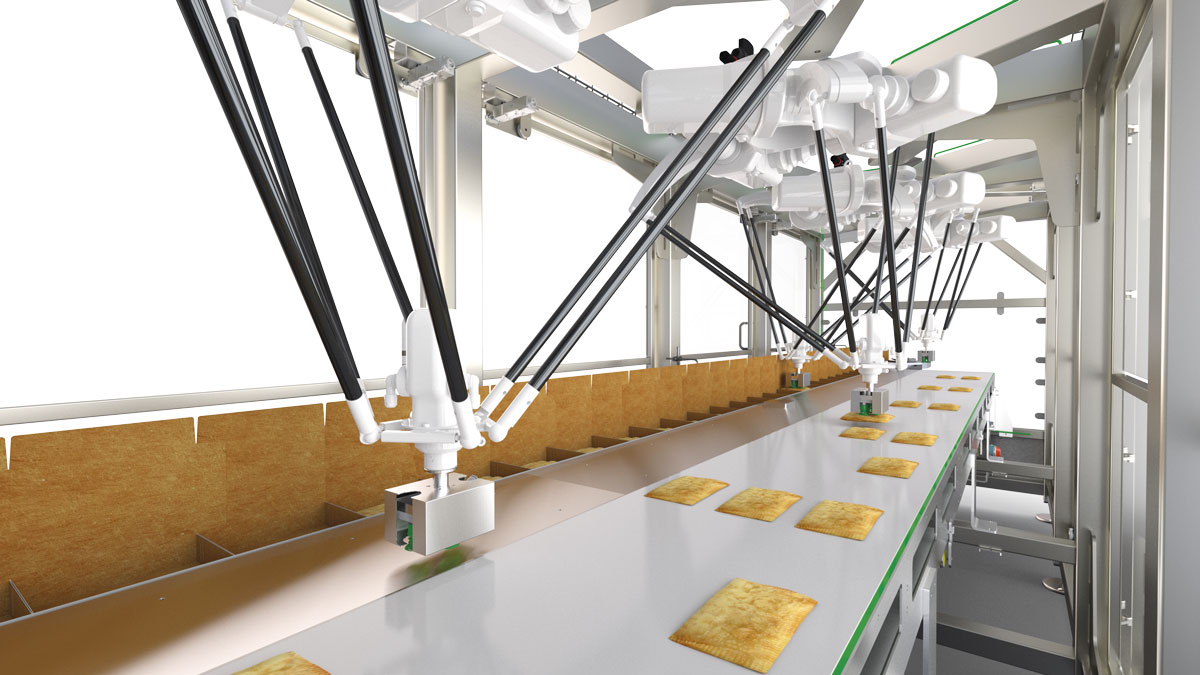

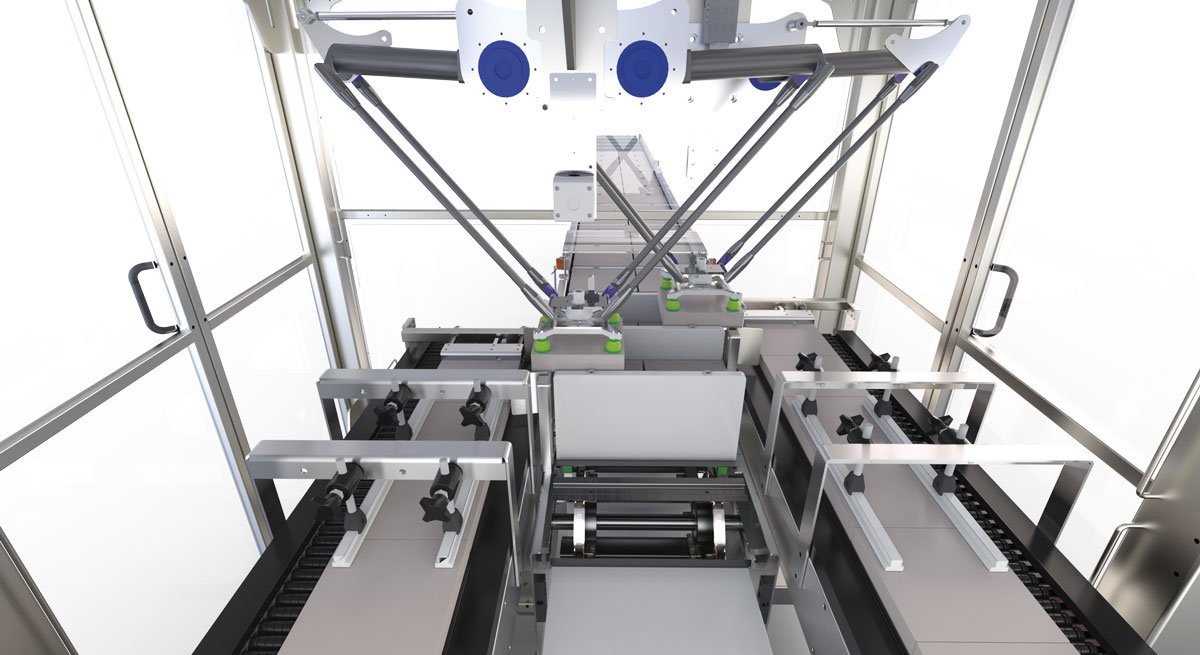

Improve your productivity by saving time moving and handling your products throughout your production line, thanks to our industrial robotics solutions. Intermittent or continuous Pick & Place: our machines adapt to the needs of your line. You can also take advantage of expert advice on robots and automated solutions to help your project move forward.

Robots to speed up the delivery of your products

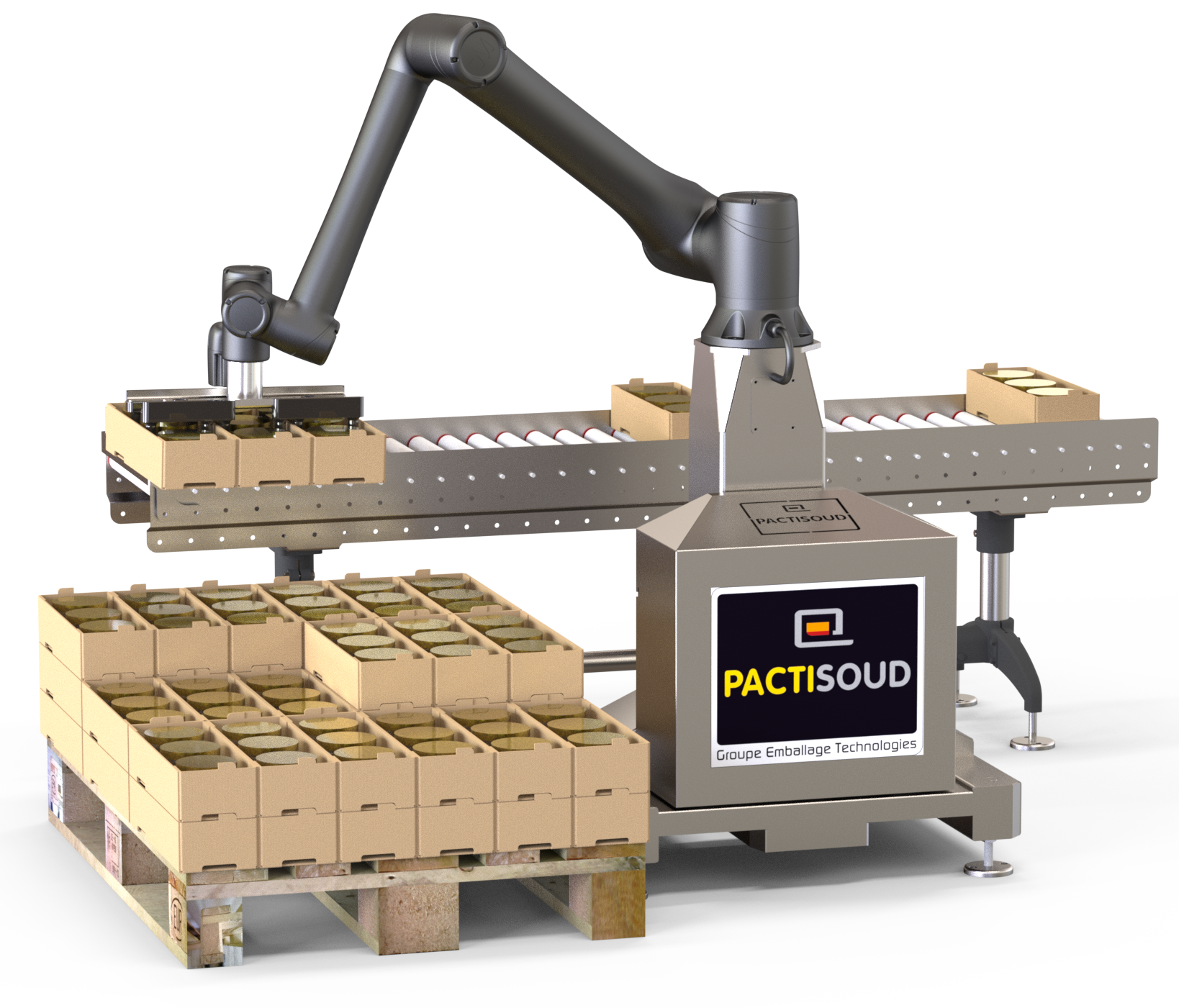

Throughout the packaging process (wrapping, cartoning, bagging, etc.), your product passes through various stages before it reaches the end of the production line and is prepared for dispatch to the end customer. This routing, throughout the production line, is one of the main time and productivity wasters in the product packaging and manufacturing process.

To reduce this loss, the Emballage Technologies group provides you with automated industrial robots that take care of conveying and handling your products throughout the production line.

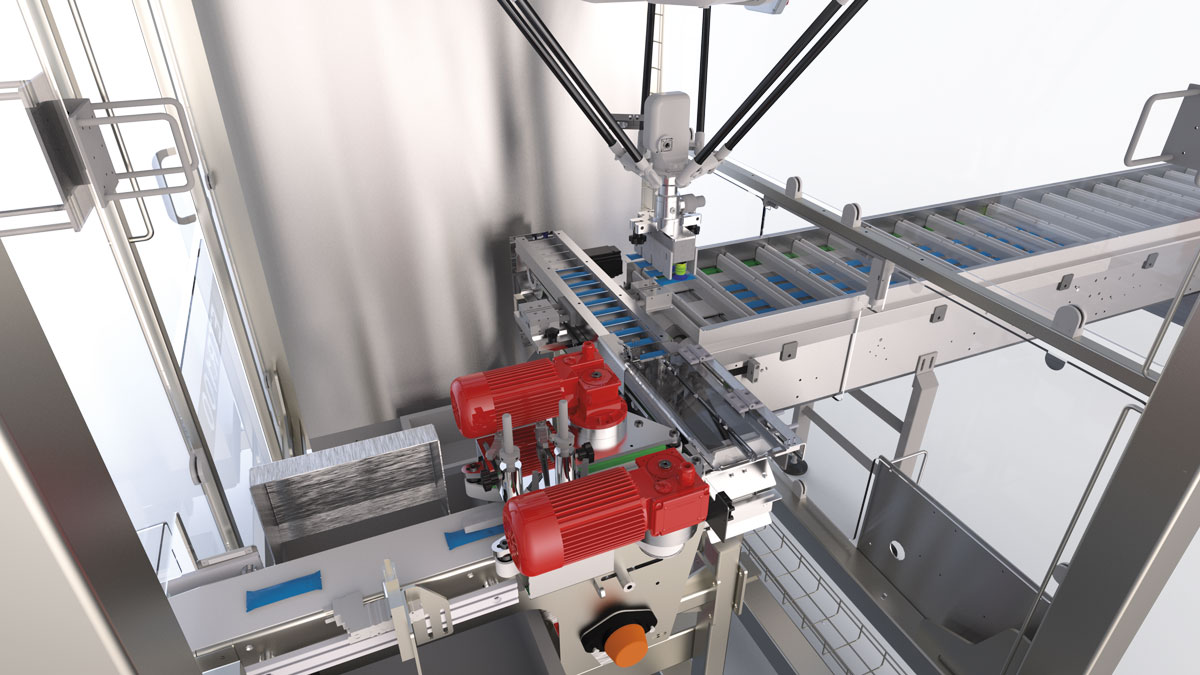

Our robotic solutions take many parameters into account, such as the weight, material and fragility of the products and their packaging, so that they can be handled as carefully as possible.

Automating the conveyance of your products saves precious time, and is something you should consider if you are looking for innovative solutions to improve the production rate of your lines.

Your machine built and configured by an expert in industrial robotics

Each robotic solution installation is supervised by technical experts from the Emballage Technologies group. Our teams define the solutions best suited to your working environment, taking into account your current processes, your needs and the configuration of your current production line.

Once your robotic and automated solution has been installed, our technical team will be happy to provide you with further details and advice on its operation and use.

Pick & Place: intermittent or content?

Our pick & place machines come in two different ranges: intermittent and continuous operation.

Intermittent" robotised Pick & Place machines

This type of machine takes care of picking and depositing products in a specific location at a regular rate, with breaks in between.

When the machine is properly configured by an operator, it follows the defined rhythm, taking care of each product thanks to its vision system. This system enables the robot to identify the proportions of the product, in order to pick it up, move it and deposit it in the best possible way, quickly and evenly, according to the automated path defined beforehand.

Continuous" robotised Pick & Place machines

Still following the operator's instructions, the robotic machine will pick up, move and place your packaged products, but this time at a pace that never stops. The actions performed per minute are impressive, and only possible when you use automated systems such as these machines.

Equip your line with an efficient robotic and automated solution

Discover our robotic solutions designed for the food, non-food, pharmaceutical and para-pharmaceutical industries. These machines, which are easy for operators to use, are guaranteed to save you time and increase your productivity as your products are transported to the customer.

Send us your specific requirements for a robotic solution using our contact form below: our team will get back to you as soon as possible to arrange a presentation meeting, where we will explain in detail the different solutions relevant to your packaging line automation project.