Palletising cobots

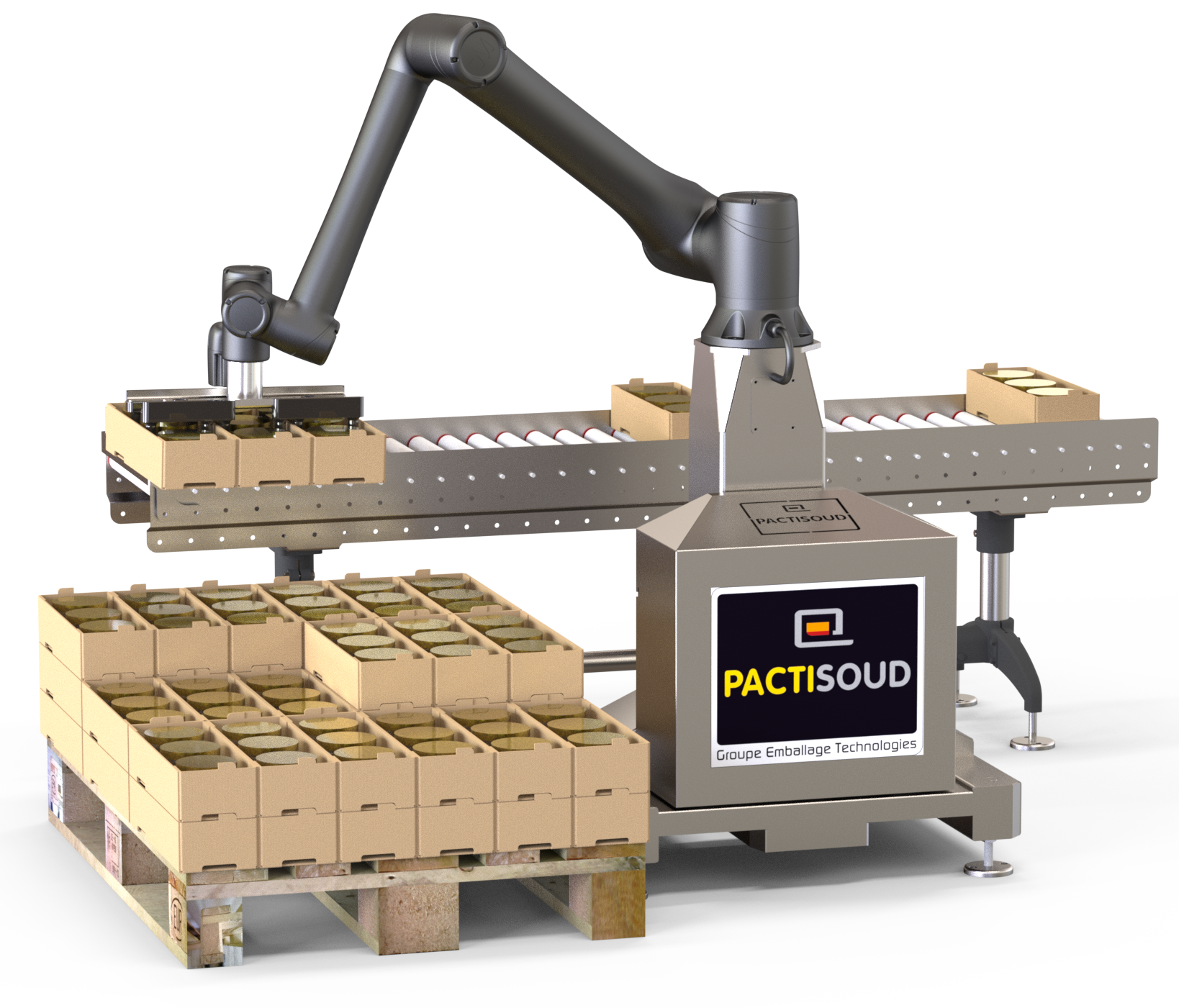

Palletising cobots are also known as collaborative palletising robots. They are automated robots designed to carry out the palletising process with great precision and safe interaction with human operators. These cobots are equipped with advanced sensors and vision systems that enable them to detect, grasp and stack products efficiently and accurately.

Cobot palletisers offer a number of significant advantages over traditional manual palletising methods. Firstly, these collaborative robots can significantly increase your company's productivity. Thanks to their speed and precision, they can carry out palletising quickly and efficiently, reducing downtime and increasing production capacity.

In addition, cobot palletisers improve operational safety. Thanks to their ability to work in collaboration with human operators, they reduce the risk of accidents and injuries linked to the manual handling of heavy loads. This also frees workers from physically demanding tasks, encouraging them to concentrate on higher added-value tasks.

Another advantage of cobots over robots is their smaller footprint. By replacing safety devices such as fences/grids with safety sensors and scanners, cobots can be integrated more easily and take up less space in the working environment. This allows greater flexibility in the layout of installations, while maintaining high safety standards.

The flexibility of cobot palletisers is also a major advantage. These collaborative robots can be programmed to adapt to a wide variety of products and pallet configurations. They can be easily reconfigured to meet the changing needs of your production line, offering a versatile solution for automated palletising.