What is a palletising robot?

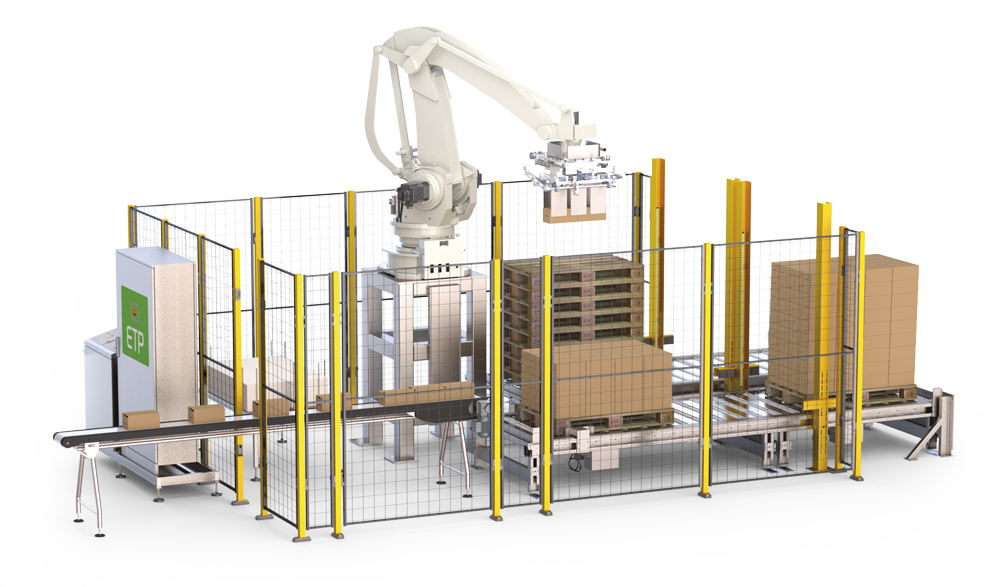

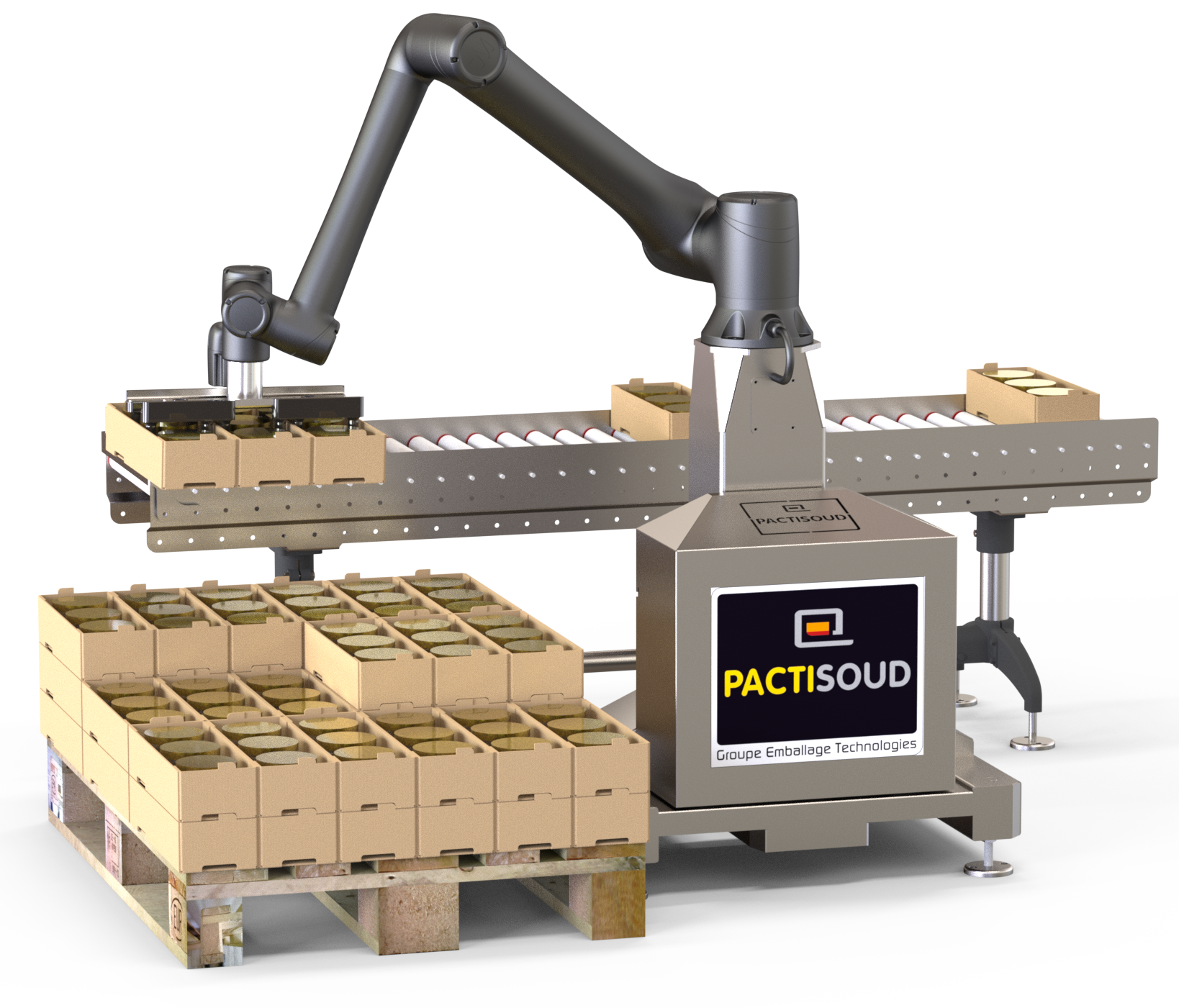

Also known as an automatic palletiser, the robot palletiser is a machine equipped with an articulated arm and a gripper, capable of handling cartons (cases) to position them ideally on a pallet support, which will then be picked up by transporters for delivery to your customers or suppliers. It therefore comes into play after the successive packing and boxing phases, thanks to a case-packing machine.

The pallet is carefully prepared by the machine: the automatic palletiser, thanks to the settings previously made by the operator, arranges the different boxes according to their weight and dimensions so that the pallet is as secure as possible during transport.

To be used by the operator, the palletising robot is equipped with software. This software enables you to set up the automatic palletiser so that it can autonomously pick up the carton from the conveyor, move it to the pallet and then organise the pallet.

All that's left to do is banderole to secure your pallet, or insert dividers to make sure the boxes don't shift during transport.

Why put your trust in a palletising robot?

The palletising robot offers major productivity gains: once configured by the operator using the software, the palletiser's articulated arm receives pallets at the conveyor outlets and then packs them into pallets according to your settings.

Palletising is particularly precise thanks to the gripper fitted to the arm, which grips the boxes perfectly and places them in the exact position you specify. The gripper is also very precise - and there's no risk of damaging the box.

Finally, the automatic palletiser also considerably reduces the risk of injury and drudgery, while also improving the safety of operators, who can focus on preparation and control actions.

Single-line or multi-line automatic palletiser?

Integrating an automatic palletiser into your production and packaging line requires space. If your conveyors carry several cartons and products that may be destined for the same pallet, opt for a multi-line robot palletiser.

Once the software has been configured, the articulated arm and gripper will pick up the cartons from the different lines in the order you specify, and place them in the layout you require. So buying a multi-line automatic palletiser instead of a single-line one frees up space - since a single robot is positioned to carry out all the operations required.

ET PACK, the palletising specialist

As well as packaging and conveying products, ET PACK supports its customers right to the end of the line by offering an automated, high-performance and secure solution.

Together, our team will define the best possible solution for palletising your boxes in the best possible conditions, based on your needs, your current organisation and your constraints.

Request a quote for the installation of a palletising robot

Save time and improve the output and productivity of your production line by opting to add a palletising robot. This solution, which addresses your productivity and organisational issues, will enable your company to unleash its full potential.

Our sales department is at your disposal: fill in our contact form to obtain more information or a detailed quotation about our machines (price, availability, technical characteristics, etc.).