Formatting cases

What is the role of the carton erector?

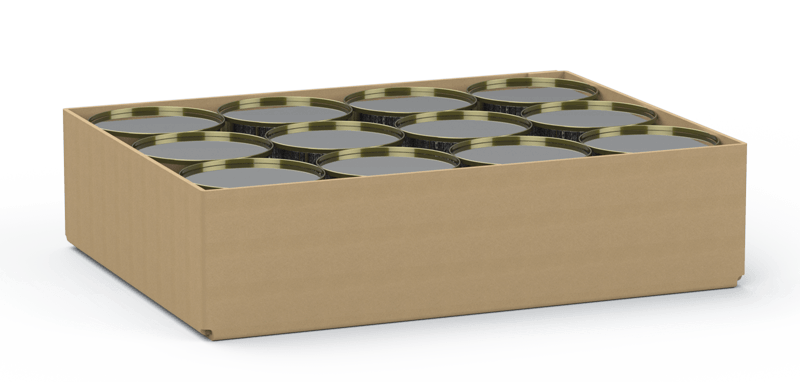

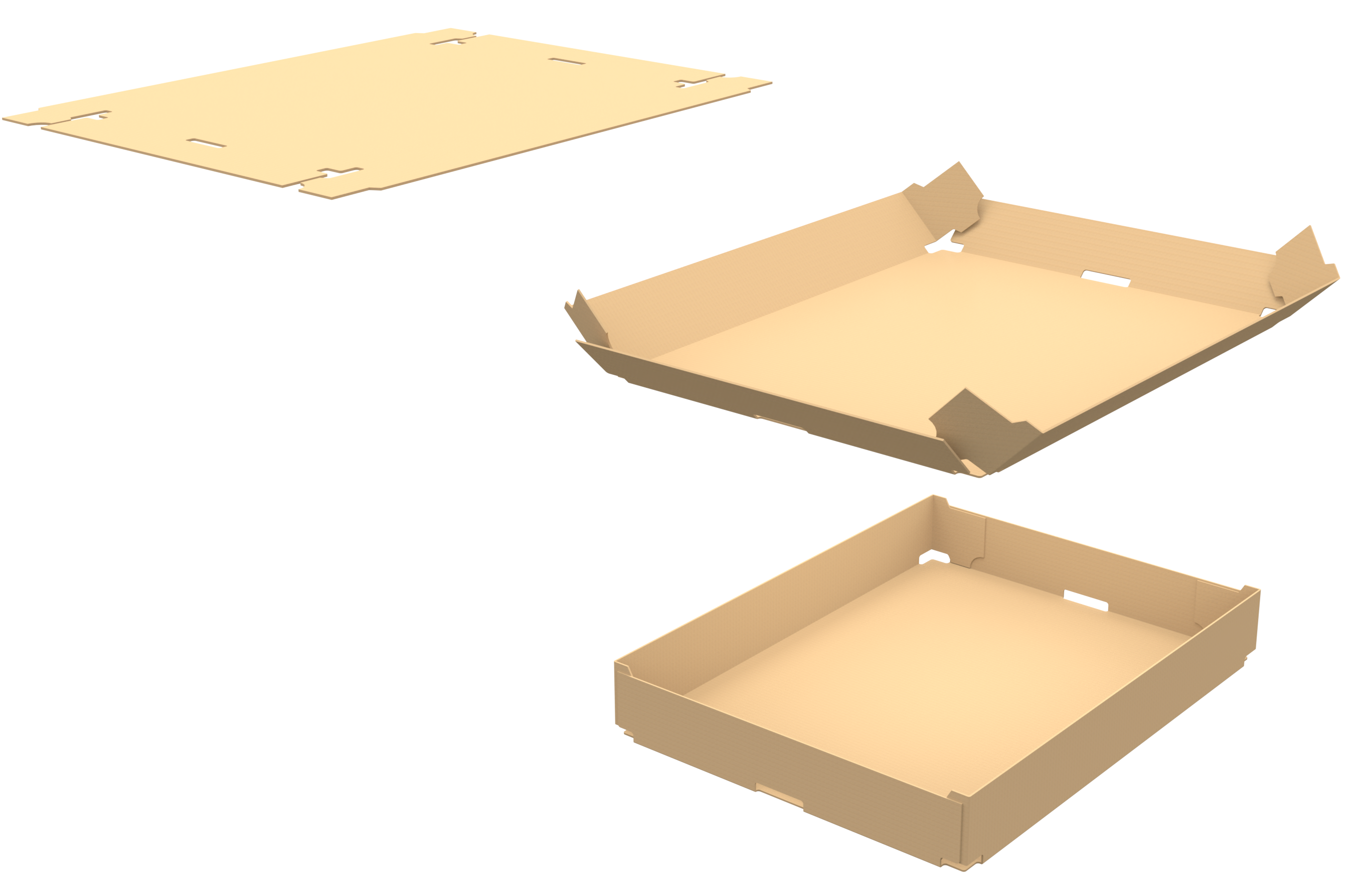

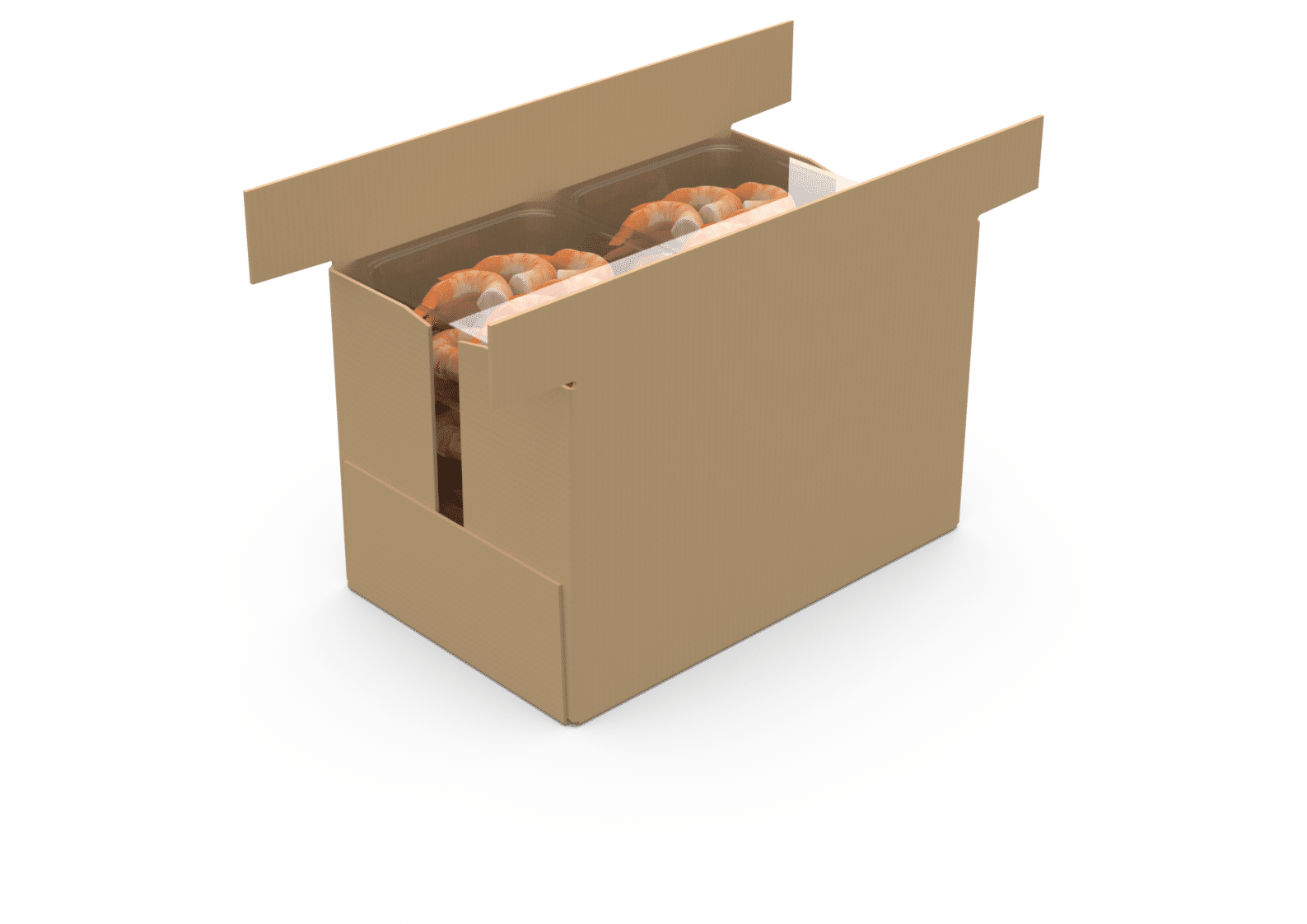

A complement to the American case packer or wrap-around case packer, the case erector automates the case forming and assembly process. Its operation is simple: it collects flat cartons and transforms them into cases ready to be filled. The machine then evacuates the cases to the case sealer, which takes care of the last stage before palletising, i.e. closing.

By opting for an automated solution, you can free operators from this task, who will be able to focus on other value-added aspects. What's more, adding a carton erector to your production line allows you to reduce potential manual errors, while guaranteeing your customers consistent packaging quality.

Case erectors can be adapted to different sizes and types of carton to meet your needs, while ensuring a rapid erection rate (up to 25 cases per minute).

What is the role of the carton sealer?

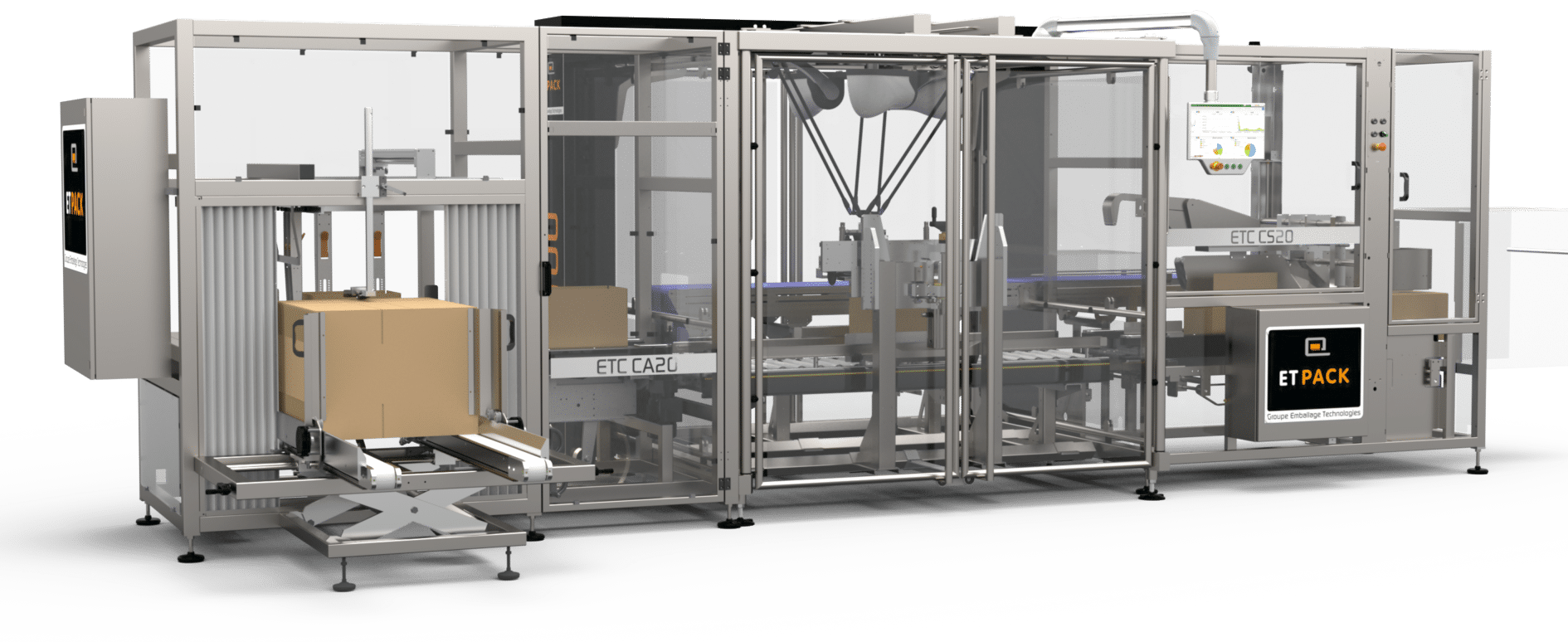

Following on from the work done by the erector, the case sealer closes the case and then palletises it before shipping. Once configured to the required dimensions, the case sealer closes the case at high speed, without interruption, and without the need for manual intervention by an operator.

This machine comprises a carton opening area, a carton magazine and an exit conveyor. The machine picks up the carton in the opening area to prepare it for shaping, before conveying it into the magazine, where it is sealed with adhesive or glue. The case then passes onto the exit conveyor, which moves the case to the palletiser for shipment.

Each case sealer can adapt the case size and shape to suit your needs. The machines can finish up to 30 cases per minute thanks to their exceptional work rate, all while ensuring a uniform, strong closure that will protect products during transport and storage.

Compact and ergonomic, the carton sealers are machines that can be easily added to existing production and packaging lines. Our machines are also equipped with a number of safety devices and signals that let operators know when the adhesive has run out or broken, so they can take the necessary action to avoid disrupting the production rate.

Adhesive or glue closure?

Carton erectors offer two types of closure: adhesive or glue. Each method has its own advantages that can be tailored to your needs.

The adhesive represents a clear cost advantage over hot-melt glue. The preparation time is also much quicker than for gluing, where a heating time is required for a perfect and neat application.

Hot-melt glue, on the other hand, offers an even stronger seal, and better resistance to variations in temperature and humidity during transport and storage of the cartons. While the preparation time is there, the glue also dries very quickly, which has absolutely no impact on the production rate.

Request a quotation for a carton erector or sealer

Improve your productivity and the quality and safety of your packaging by adding a case erector and case sealer to your packaging line. Emballage Technologies' technical and sales teams will help you optimise your production line.

With over 30 years' experience in product packaging, we can offer our customers ever more innovative and effective solutions.

Request a quote using our contact form: we'll get back to you as soon as possible with the documentation and information you're looking for.