A production or packaging line represents a major investment in the life of a company. The choice of machinery is just as important as the layout and installation of the components to ensure that the production and packaging process is as efficient as possible.

Our design office understands this, and offers you a unique service, based on virtual reality, so that you can preview your future packaging line in your everyday environment.

Total immersion in your project

Virtual reality is a technology with many applications. While the general public is familiar with it for its use in certain forms of entertainment, such as video games, professionals have embraced VR to offer their customers a superior quality of service.

Innovation is one of ETPACK's priorities. The use of this technology in other sectors has aroused the curiosity of our engineers, who have worked to integrate it into our work process.

A collaborative process right from the pre-sales stage

In the pre-project phase, our sales team takes charge of analysing your company's needs. But this work is not limited to discussions between the customer and the supplier: we also include your employees - those who will be using or working directly on the packaging line. Their expertise is essential in assessing the ergonomics and practicality of the workstations and any technical constraints linked to your production environment.

Virtual reality makes it possible to visualise your future line in detail, and to gather feedback from operators on practical aspects such as machine accessibility or the layout of workstations requiring human intervention. This collaborative approach ensures that your packaging line will be functional, intuitive and tailored to your needs.

Technology at the service of our sales team

Integrating virtual reality into the sales process enables our teams to better understand customer expectations while offering them a unique and interactive experience.

When we first make contact, our sales team takes charge of understanding the customer's specific packaging requirements. A detailed brief is then drawn up, summarising the objectives, technical constraints and priorities of each project.

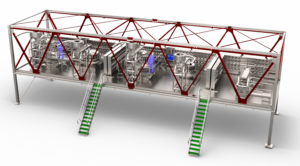

Based on this brief, the sales representative uses virtual reality to present the customer with an initial sketch of the future packaging line, in a simulated environment. This allows us to discuss the choice of machines and layout in more concrete terms, and to make changes in real time based on feedback from the customer. Immersion in this virtual space enables our customers to visualise their expectations much more precisely than with traditional plans or 3D renderings.

By immersing your teams in a virtual reality simulation, we help you take a step back from the overall design of your project. This technology provides an overall vision that helps you to better understand the interactions between the various elements of the line and to validate critical stations, particularly those requiring human intervention. This avoids many ergonomic or design errors during the installation phase.

VR, an asset for our design office

When defining the project with the customer, the sales representative draws up a full brief summarising all the technical requirements.

This brief is used as the basis for modelling the packaging line in virtual reality: our engineers can select and integrate coherent machines for each customer, whose 3D plans are saved in the VR software.

The sales representative also collects photos of the customer's working environment to enable our engineers to recreate the production site accurately, while incorporating the solutions chosen for the creation of a new packaging line.

This modelling of our machines in our customers' working environment is invaluable: it enables our design office to check that the line is perfectly installed, and that it is successfully integrated into the wider working environment.

In fact, virtual reality is one of the tools our team uses to ensure that the project is as coherent and high-quality as possible, taking into account the needs expressed during the initial meetings with our sales team.

Innovative technology tailored to our customers' needs

Virtual reality has also established itself as a valuable asset for our customers.

Unlike 3D plans, virtual reality offers exceptional interactivity, enabling users to visualise the operation of their future packaging line down to the last detail.

Once the helmet is on your head, you can move around the various machines using the joysticks. This gives you the most authentic possible view of the final result on your production site, several weeks or months before the installation is completed.

This unique, concrete and real perception of their future working environment allows them to project themselves further into their project. Thanks to virtual reality, our customers can be sure that their investment in their packaging line meets their expectations from a practical, ergonomic and technical point of view.

Validate the design with a Pre-FAT

Before we send you off to production, we offer you a Pre-FAT (Factory Acceptance Test) directly in the virtual environment. This stage is crucial for making last-minute adjustments, in collaboration with your teams. It enables us to check that all the elements meet the functional, ergonomic and operational requirements before the production phase.

Virtual reality: a strategic tool for all your projects

Virtual reality offers incomparable advantages throughout your project:

- Greater collaboration between your teams and our experts, encouraging the exchange of ideas and the identification of the best solutions.

- Ergonomic and technical validation before installation, avoiding costly and time-consuming errors.

- Coherent integration of machine entities and know-how from all ETPACK Group companies (ETPACK - PACTISOUD - SERMATEC) for optimised, high-performance packaging lines.

Finally, virtual reality is a real innovation lever for your company, enabling you to visualise, test and validate every detail of your project, while involving your employees in this participative approach.

Entrust your project to the ETPACK teams

Are you planning to extend your packaging line to improve the production rate of your packaging? Do you want to develop a new type of packaging at your site and need a brand new line?

Let's discuss your project together: innovation, whether in our machines or in the service we offer our customers, will enable us to meet your needs and provide you with the best possible support in setting up this brand new line.

Fill in our contact form and our team will get back to you as soon as possible.