PACTISOUD, is proud to present its conveyor specifically designed to feed ovens.

This conveyor has been installed at one of our customers, a major player in the meat industry.

The challenges of oven input/output supply

Feeding the furnaces is a recurring issue PACTISOUD's customers. The combination of the high temperature, the large winding diameter of the oven and the size of the products complicates the transfer. These constraints can lead to problems with jammed or overturned productsThis can affect their quality and slow down production.

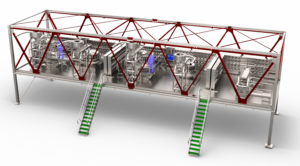

PACTISOUD's special conveyor: a made-to-measure solution

To remedy these problems, PACTISOUD offers a special conveyor allowing fine adjustments. This conveyor incorporates transfer boxes with handwheels to adjust the length of the conveyor and its height independently to the millimetre.

What's more, you can opt for a motorised transfer roller upstream, enabling even the smallest products to be conveyed without a hitch.

Conclusion

PACTISOUD's new conveyor is the ideal solution for machine interfaces such as ovens, gyros, etc.... Thanks to its specific settings and respect for the product, it improves productivity and the repeatability of settings.

To find out more about our new conveyor and our other conveyor solutions, please contact us. We'll be delighted to answer your questions and help you with your projects.

At PACTISOUDwe are committed to providing innovative solutions adapted to the challenges of modern industry. Our retractable conveyors are proof of our commitment to innovation and quality. To find out more about these revolutionary systems and how they can transform your production line, visit our website and contact us. Our team is ready to help you optimise your material handling process with solutions that are both efficient and hygienic.