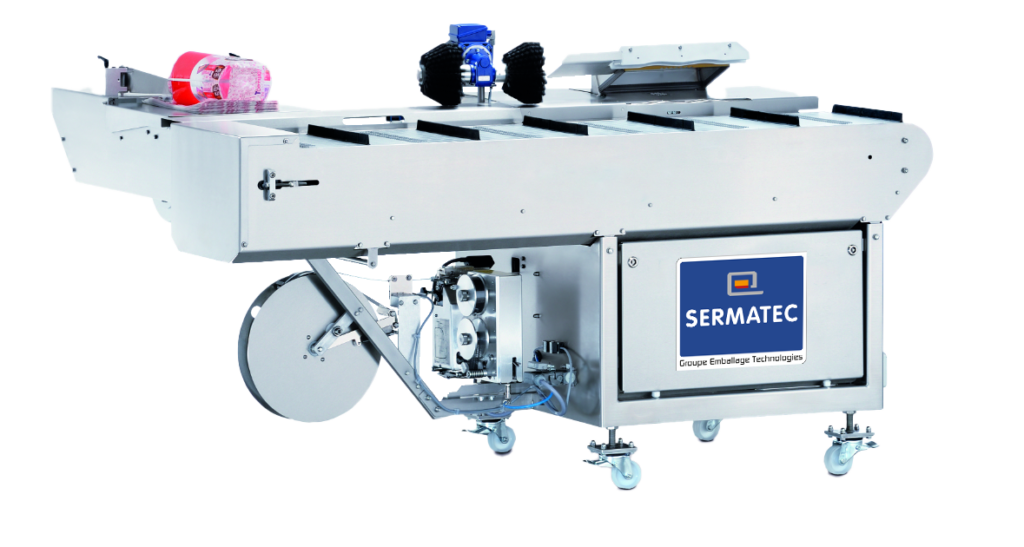

Our EC101 HS clip-on machine is designed to handle various types of pouch: polyethylene (PE), polypropylene (PP) and paper. This machine combines robustness and cutting-edge technology for optimum packaging of your products.

Project background

The customer wanted a packaging solution that not only ensured the secure closure of the pouch, but also offered an aesthetically pleasing presentation. In addition, it is essential that the sachets can be easily opened and resealed, which is achieved through the use of a clip.

Description of operation

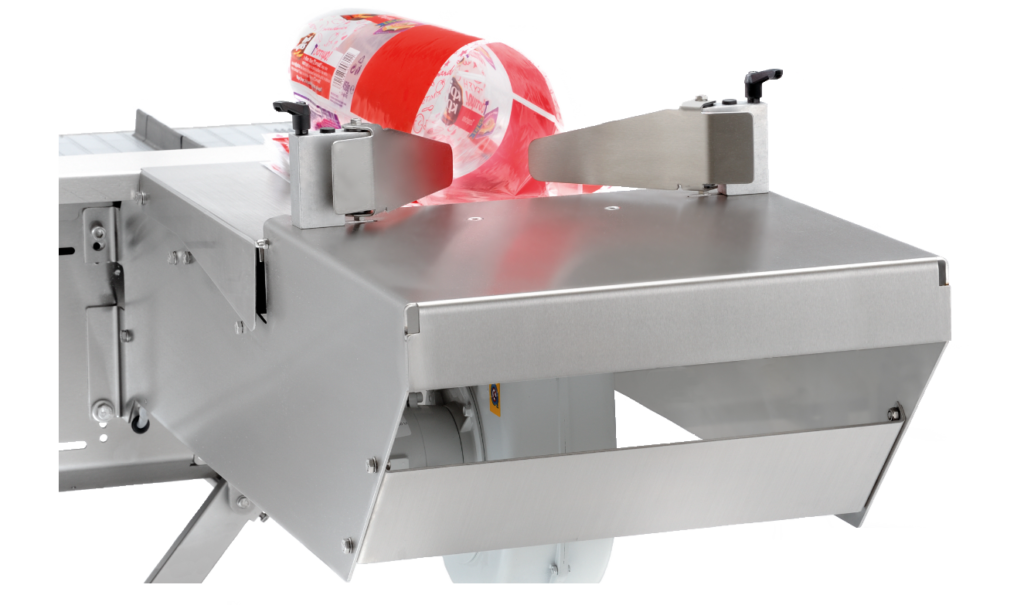

Bagging table

The bags are first opened using the bagging table. This allows the different types of bread, whether whole or sliced, to be manually inserted into the film. The products are then placed transversely on the conveyor belt.

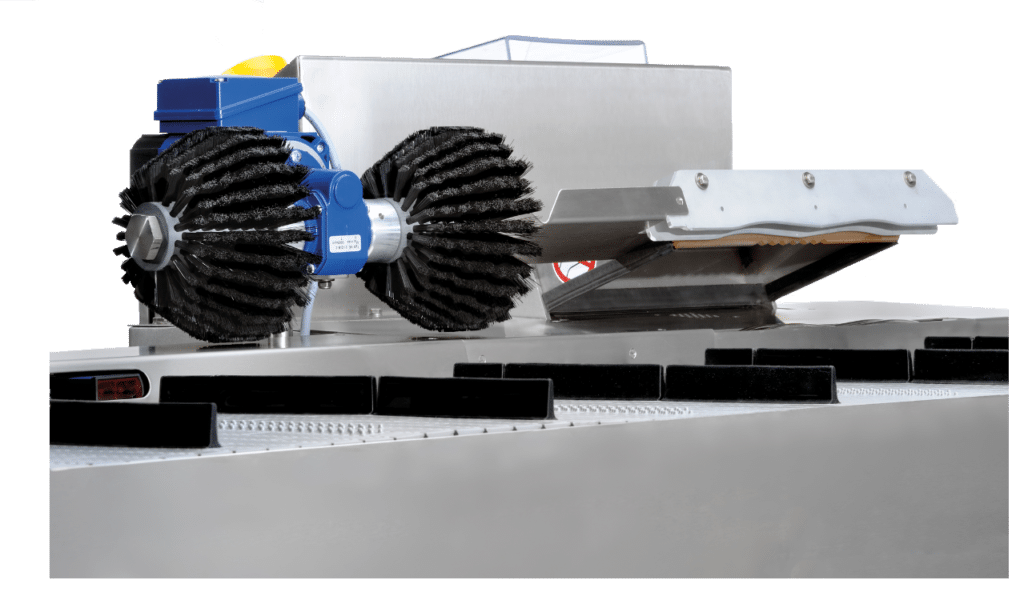

Conveyor and Alignment

After bagging, the products are aligned using brushes and automatically conveyed to the sealing station. This smooth transition is essential to maintain a production rate of 40 bags per minute, i.e. up to 2,400 bags/hour.

Closing Station

Before closing, an integrated vacuum device sucks out any excess air, ensuring compact, secure packaging. The final clipping is carried out with precision, guaranteeing the preservation and quality of the packaged product.

Additional options

Marking device on the clip: personalise your clips with a marking device.

Rotary table Packaged products can be transferred to a turntable before being picked up manually or automatically. This facilitates the collection of packaged products and optimises production flow.

Benefits

- Flexibility of movement: thanks to its wheels and compact design, it can be easily moved and positioned in the desired work area.

- Multi-format machine, adjustable without tools, in less than 3 minutes.