Grouping solutions tailored to your needs

We develop tailor-made solutions to manage the grouping of buns at the cooler outlet. Depending on the arrival of the products and the production rate, our systems ensure that the buns are brought back on line, while guaranteeing their integrity.

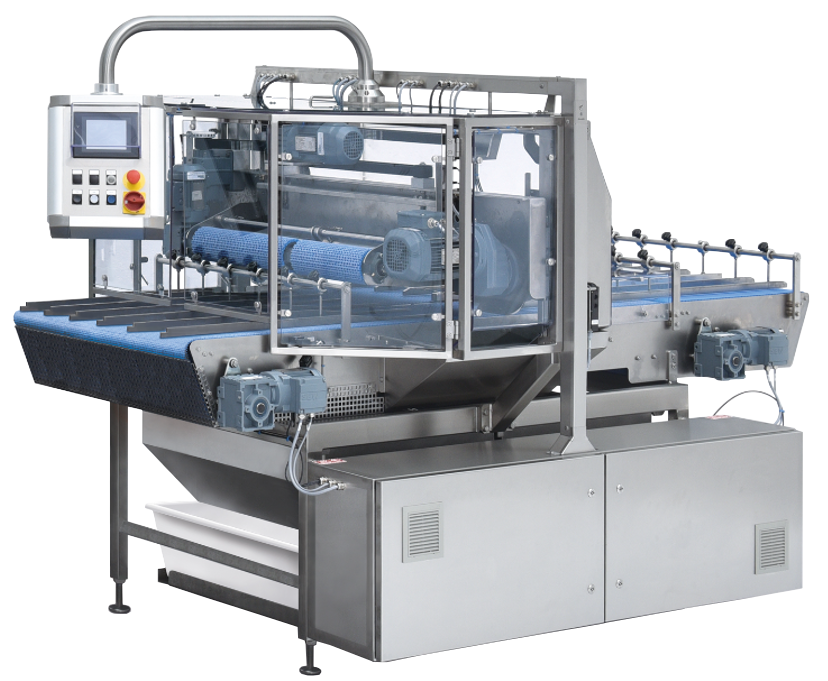

After the buns are brought back into line, they are distributed over several lanes on an accumulation belt, followed by the adjustable grouping station.

Wallet, butterfly or full slicing

Our machines can integrate disc slicing for wallet or butterfly cutting directly into the production flow and upstream of bundling. For complete slicing after bundling, we use a ribbon blade.

Product features HB :

- For baguettes, hot dogs and buns

- Up to 30m/min

- Maximum height of 80mm

- Multichannel

HS product features :

- For baguettes, hot dogs and hamburger buns

- Up to 300 products/min

- On a 1 or 2 lane

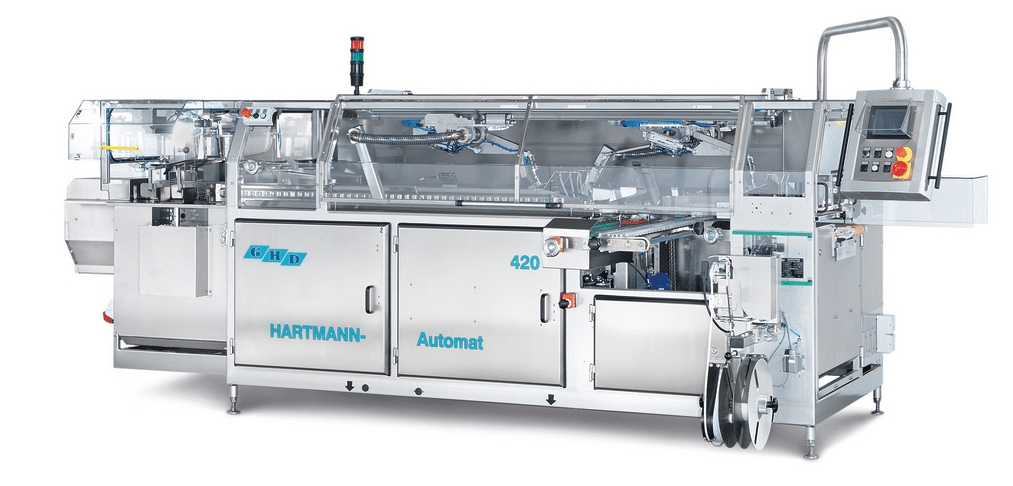

Automated packaging: efficiency and speed

The bundles are loaded by motorised transfers into a flowpack or GBK type pre-formed bagging machine. This automation guarantees high speeds, careful handling and product integrity of up to 65 products per minute.

Your buns deserve the best

Whether you need partial or complete slicing, or a high-performance packaging system, we offer solutions tailored to your speed and quality requirements.